Zirconia offers a unique balance of hardness and toughness, making it stand out among all ceramic materials.

Provides long service life even under high-speed operation.

Reduces the risk of cracking and mechanical failure.

Performs stably in acid, alkali, and saltwater environments.

Maintains low friction and minimal expansion under varying temperatures.

Perfect for use in applications requiring clean,non-conductive materials.

Manufactured from premium ZrO₂ powder

Ensures smooth surface finish and dimensional accuracy

Guarantees reliable performance and long service life

Bearings designed to meet specific industrial needs

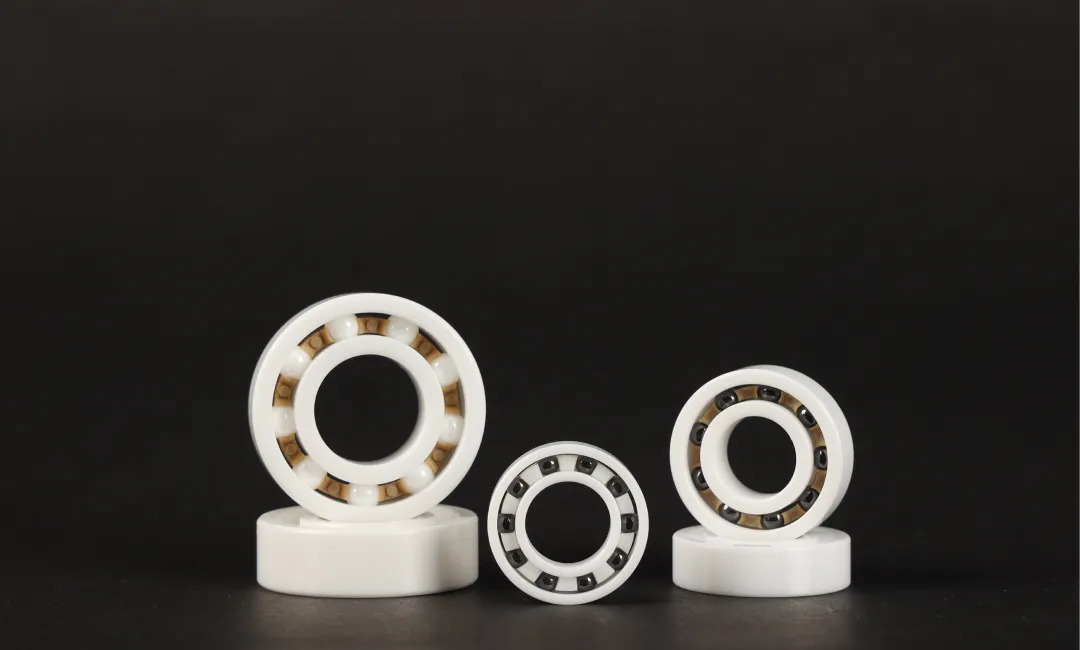

A ceramic bearing is a bearing made from advanced ceramic materials such as zirconia(ZrO2) orsilicon nitride (SizN4). Compared to traditional steel bearings, ceramic bearings are lighter, harder,corrosion resistant, and capable of high-speed operation.

Weight:Ceramic bearings are~75% lighter than steel bearings. Friction: Lower friction, which allows higher speed and efficiency. Corrosion resistance: Ceramic bearings resist chemicals and moisture. Durability: Ceramic is harder and more wear-resistant,resulting in longer service life.

Zirconia bearings typically withstand temperatures up to 600°C. For higher temperature applications, silicon nitride bearings may be preferred.

No. Zirconia and silicon nitride bearings are non-magnetic, which makes them ideal forapplications where magnetic interference must be avoided, such as in electronic equipment andMRI machines.

Zirconia: Better toughness, corrosion resistance, suitable for wet or chemical environments. Silicon Nitride: Better high-speed and high-temperature performance, slightly lighter, but lower toughness.

Zirconia bearings offer: High hardness and wear resistance Excellent toughness and impact resistance Corrosion and chemical resistance Non-magnetic and electrically insulating properties Lightweight and energy-efficient operation These features make them suitable for aerospace, medical, marine, and precision machinery applications.

Yes. Many zirconia ceramic bearings can operate without lubrication, especially in clean-room, vacuum, or high-temperature environments. However, in heavy-load or continuous-speed applications, light lubrication is recommended to extend lifespan.

Absolutely.Zirconia ceramic bearings are highly resistant to acids, alkalis, and saltwater, making them ideal for chemical processing,marine, and medical applications.

The lifespan depends on load, speed, and operating conditions, but zirconia ceramic bearings generally last 2-5 times longer than steel bearings under similar conditions due to their wear resistance and chemical stability.

Ceramic bearings can replace steel in most high-speed, corrosion-prone, or precision applications. However, for heavy shock or ultra-high load industrial applications,careful evaluation is required as ceramics are harder but less forgiving under extreme impacts.