Luoyang SHIBO Precision Bearing Co., Ltd. is a company specializing in the research and development, production and sales of high-precision special bearings. Our product range includes deep groove balls, self-aligning balls, thrust balls, outer spherical balls, angular contact balls, etc. We offer standard and non-standard materials.

Countries & Regions Of Sale

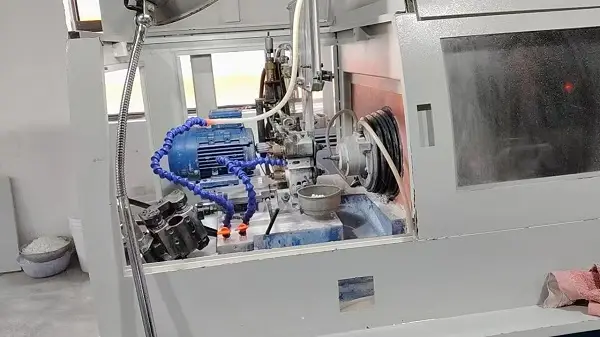

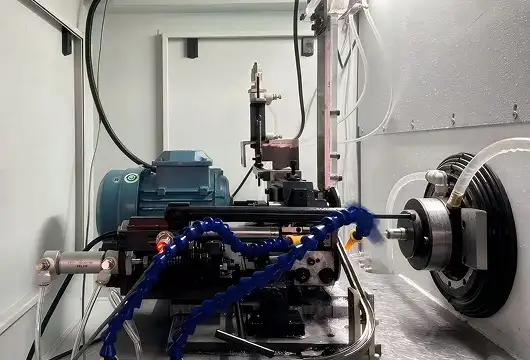

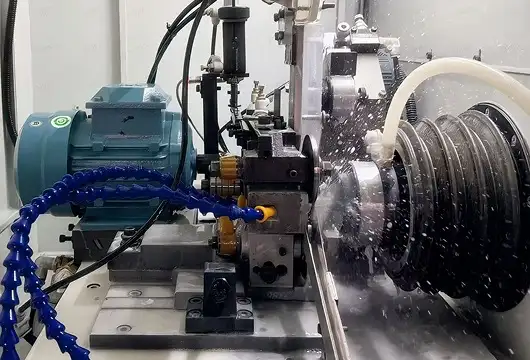

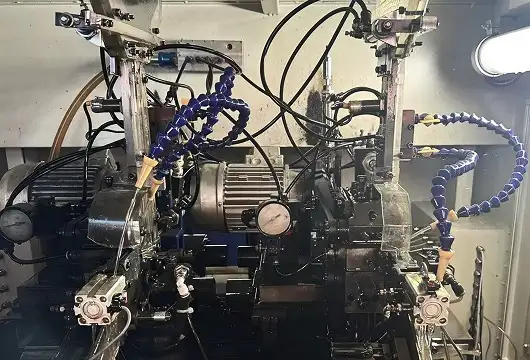

Processing Equipment

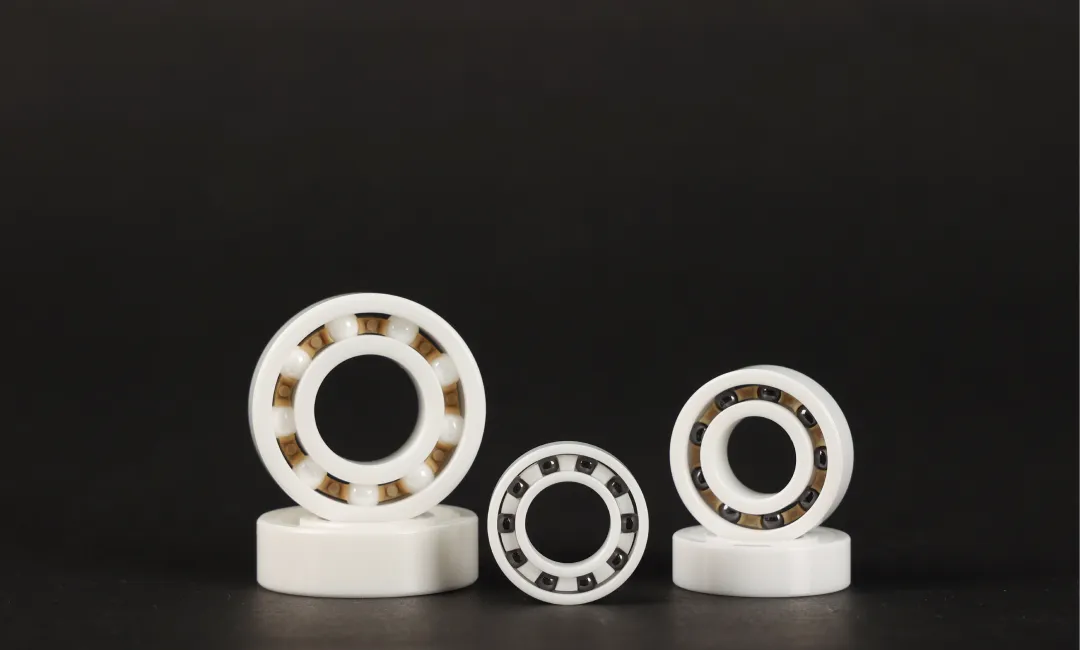

Processed Products