Time: 2026-01-06 05:41:26

Blank → Surface Grinding → Centerless Grinding (Outer Diameter) → Rough Grinding (Inner Diameter) → Fine Grinding (Inner/Outer Groove) → Ultra-precision

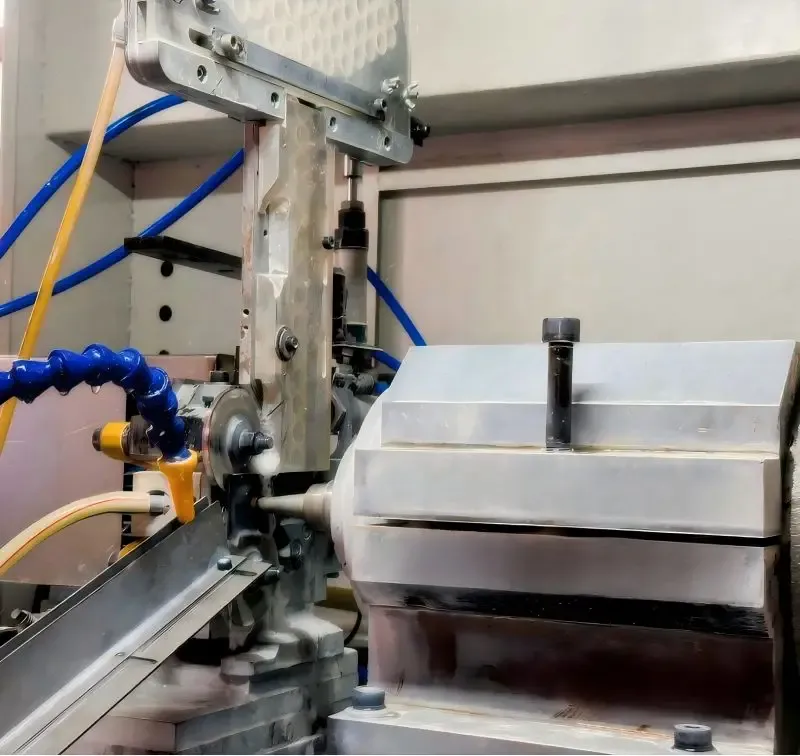

(I) Surface Grinding Operation Method:

1. Upon arrival of the blank, first measure the allowance. During the measurement process, randomly sample five different points and record the precise allowance value.

2. Place the blank into the grinding machine chuck. Measure at least three times to obtain the optimal process dimension (finished height dimension).

3. The surface grinding machine can be set with dimensions. After the first pass, the required dimensions will be known.

4. Depending on the height of each product model, the optimal tolerance for all models should be between 0.01-0.02mm (1 micrometer), i.e., within 1 micrometer.

5. The parallelism difference of the surface should be within 0.002mm.

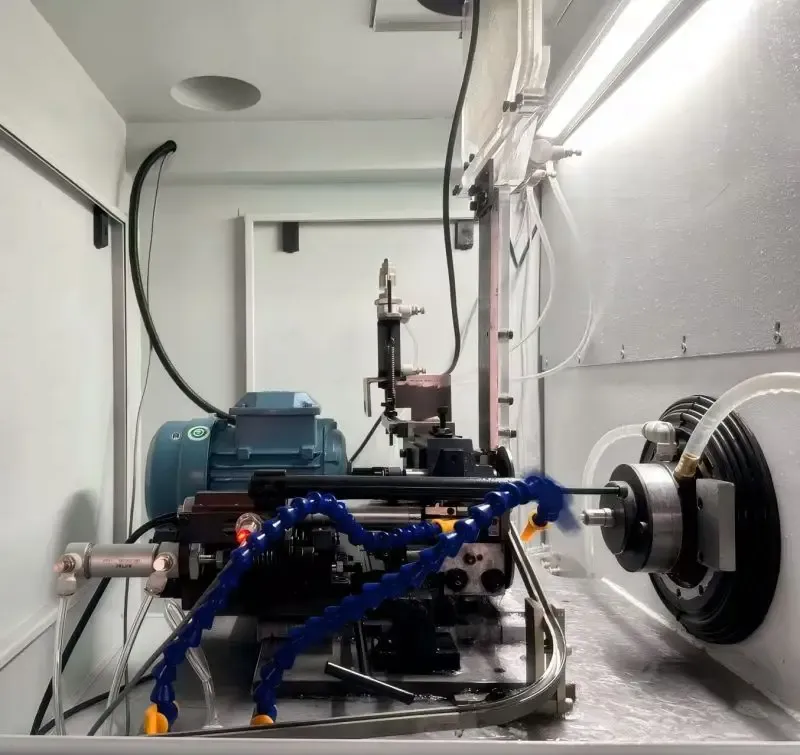

(II) Centerless Grinding Operation Method for Inner and Outer Ring Outer Diameters:

1. Before machining the outer diameter of the inner and outer rings, first measure the allowance.

2. For the first pass of machining the outer diameter, it is best to grind no more than 5 microns. After the outer diameter is rounded, subsequent passes can be made with more passes, as long as the diameter reaches the specified dimensions. For the last two passes, it is recommended to grind no more than 3 microns each to ensure quality.

3. Pay attention to grinding damage on the outer diameter during the machining process.

4. The outer diameter wall thickness tolerance should be within 0.002mm.

5. There is a standard part for the outer diameter dimensions. Dimensions: based on the standard part; Tolerance: between (-0.002) and (-0.005)mm; Taper: within 0.002mm.

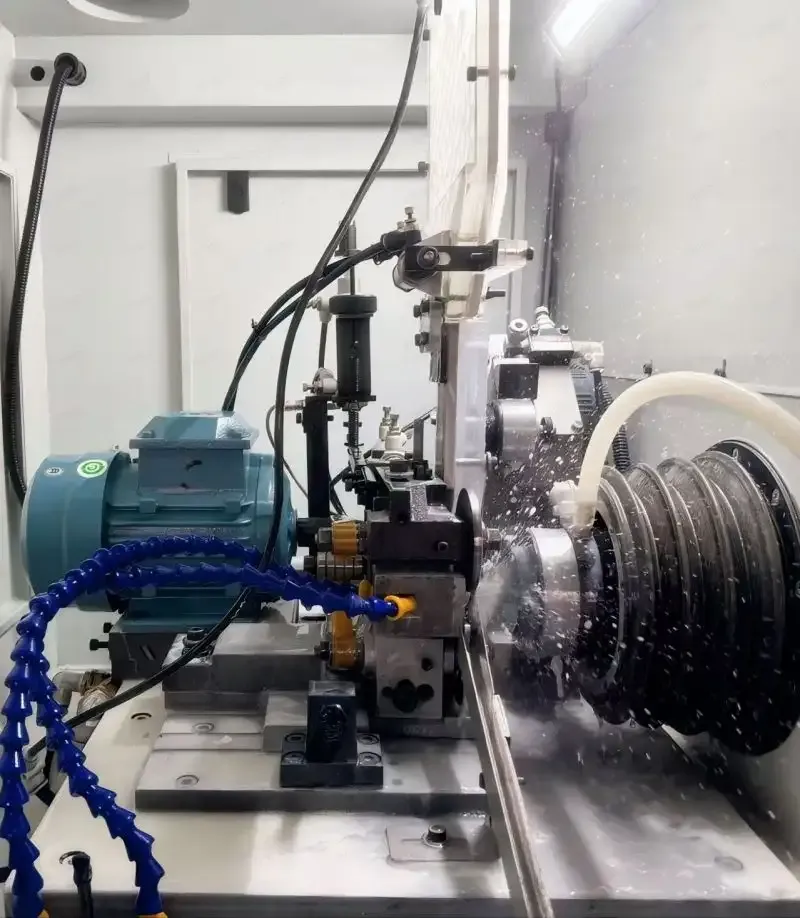

(III) Rough Grinding Operation Method for Inner Diameter:

1. When machining the inner diameter, first measure the allowance from the rough inner diameter blank to the finished product;

2. After the workshop foreman changes the machine tool model number, the operator must align the standard part with the measuring instrument. The machined product should conform to the standard part and the process specifications.

3. The rough grinding dimensions should leave allowance for fine grinding according to each model, with a allowance of 0.04-0.05mm. Taper should be within 0.005mm, and ellipticity within 0.005mm.

4. The inner diameter wall thickness tolerance should be within 0.002mm.

(IV) Fine Grinding Operation Method for Inner Diameter:

1. When machining the inner diameter, first measure the allowance from the rough grinding to the finished product;

2. After the workshop foreman changes the machine tool model number, the operator must align the standard part with the measuring instrument. The machined product should conform to the standard part and the process specifications.

3. The dimensions of the fine grinding process are based on the process and standard parts.

Dimensional tolerance: (-0.002)--(-0.005) mm,

Taper within 0.002 mm, ellipse within 0.002 mm.

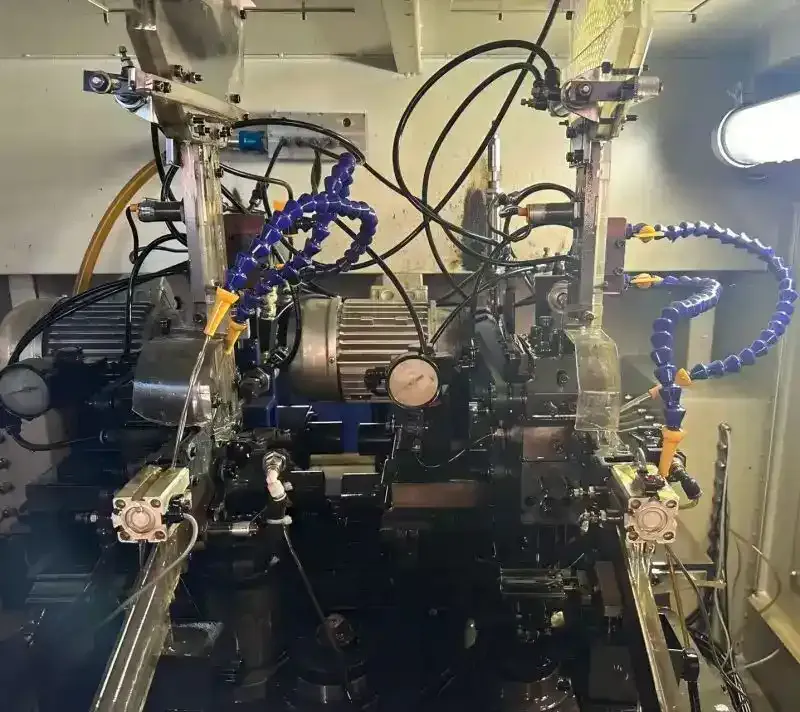

(V) Internal groove machining operation method:

1. First, perform rough grinding of the internal groove. The operator first changes the machine tool model. After changing, the operator first aligns the instrument with the standard parts. The first piece is recorded according to the process. The rough grinding groove should leave an allowance of 0.08-0.1 mm for the fine grinding groove. The ellipse of the rough grinding internal groove should be within 0.003 mm. Groove curvature: based on the scraping ball, groove placement within 0.005 mm, groove position within 0.005 mm.

2. The second step is fine grinding of the inner groove. The operator first changes the machine tool model. After changing the model, the operator aligns the instrument with the standard parts. The fine grinding dimensions of the inner groove are recorded based on the standard parts. The ellipse of the inner groove should be within 0.002mm, the groove curvature should be based on the scraping ball, the groove placement should be within 0.002mm, and the groove position should be within 0.003mm.

(VI) External Groove Machining Operation Method:

1. First, rough grinding of the outer groove is performed. The operator first changes the machine tool model. After changing the model, the operator aligns the instrument with the standard parts. The first piece is recorded based on the process. The rough grinding groove should leave a allowance of 0.08-0.1mm for the fine grinding groove. The ellipse of the outer groove should be within 0.003mm, the groove curvature should be based on the scraping ball, the groove placement should be within 0.005mm, and the groove position should be within 0.005mm.

2. The second step is fine grinding of the outer groove. The operator first changes the machine tool model. After changing the model, the operator aligns the instrument with the standard parts. The fine grinding dimensions of the outer groove are recorded based on the standard parts. The ellipse of the outer groove should be within 0.002mm, the groove curvature should be based on the scraping ball, the groove placement should be within 0.002mm, and the groove position should be within 0.003mm.

(VII) Ultra-precision machining operation method:

1. After changing the model, the operator must select the correct ultra-precision oilstone, choosing the appropriate width based on the product's groove curvature.

2. First, grind the oilstone to the correct curvature, grinding to the product's radius (R) before proceeding with machining. Products in the initial break-in period are then loaded for ultra-precision machining.

3. Qualified products are inspected using a magnifying glass. Qualified and unqualified products show different smoothness under magnification. Finally, check if the groove diameter has decreased and if the groove curvature has changed shape.

Note: After ultra-precision machining of the inner groove, it is best to place it in a material tray to prevent scratching. When assembling and cleaning, care should be taken to prevent friction or contact between the inner channels.